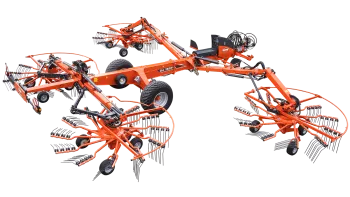

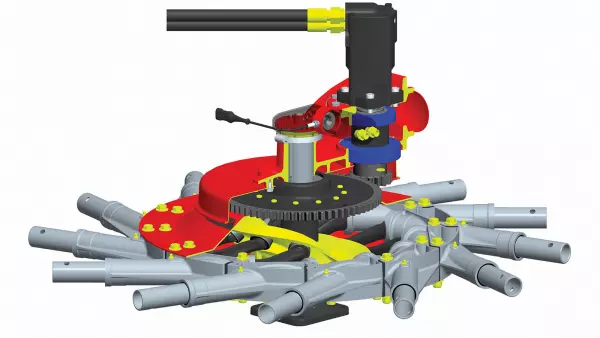

Exklusiv: hydraulischer Antrieb auf allen vier Kreiseln

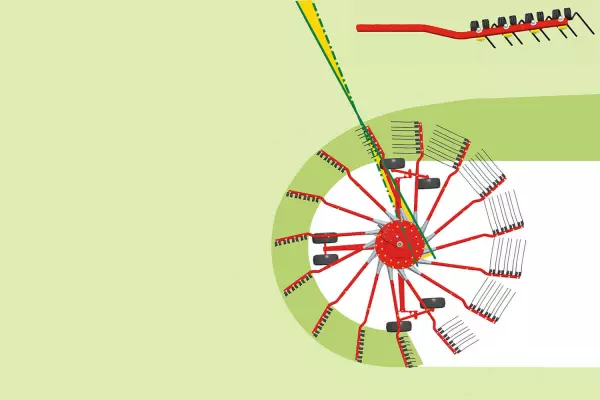

Eine Stunde weniger Wartung, eine Stunde mehr Schwaden! Der Antrieb der Kreisel erfolgt hydraulisch über Hydraulikpumpen, die von einem einzigen Getriebe angetrieben werden. Dies minimiert den Wartungsaufwand erheblich, da das tägliche Abschmieren der Gelenkwellen entfällt. Im Vergleich zu einem mechanisch angetriebenen Schwader gleicher Größe sparen Sie bis zu einer Stunde. Dies ist bei steigenden Flächenleistungen und kleinen Erntefenstern ein erheblicher Vorteil.

Weitere Vorteile sind der ruhige, leise Lauf und der geringe Verschleiß. Das Hydraulikaggregat der Vierkreiselschwader ist auf dem schwenkbaren Anbaubock des Maschinenrahmens positioniert. Dadurch sind auch enge Kurvenfahrten problemlos möglich. Zusätzlich kann die Zapfwellendrehzahl von der Kabine aus verändert werden, um sich optimal an Art und Menge des Erntegutes anzupassen.

Weitere Vorteile sind der ruhige, leise Lauf und der geringe Verschleiß. Das Hydraulikaggregat der Vierkreiselschwader ist auf dem schwenkbaren Anbaubock des Maschinenrahmens positioniert. Dadurch sind auch enge Kurvenfahrten problemlos möglich. Zusätzlich kann die Zapfwellendrehzahl von der Kabine aus verändert werden, um sich optimal an Art und Menge des Erntegutes anzupassen.